gs97034-1 manual abrasion test耐磨测试

surfacetest of motor vehicle interior materials

汽车内饰件材料表面测试

manual abrasion test

耐磨测试

1、scope andpurpose适用范围及目的

interiorsurface materials are subject to friction forces caused by fingers, parts ofthe hand or other body extremities, this group standarddescribes the manual abrasion test and applies to coated and uncoated surfacematerials.

内饰表面材料受手指手或身体其他部位的摩擦此集团标准阐述磨耗测试适用于有

涂层与无涂层的材料表面。

thepurpose of this group standard is to determine a standardized test forevaluation of the chemical and physical suitability of the material.

此标准目的在于定义评价材料的化学和物理适用性的测试标准。

therange of the parts to be tested must be coordinated with the respectivespecialist department.

零部件需要测试的范围必须分别与专业部门协调。

2、normativereferences引用标准

thisstandard incorporates provisions from other publications. these normativereferences are cited at the appropriate places in the text and the publicationsare listed hereafter. the respective latest edition of the publication isapplicable.

本标准引用来自其他出版物的规定。这些规范性文献在文中适当的位置引用及出版物

中列出。此后各自Zui新的版本是适用的。

din 50014 climates and their technical application;standard atmospheres

气候与其应用技术标准大气压

din en 20105--a02 textiles; tests for colour fastness;part a02:

grey scale for assessingchange in colour

纺织品;染色色牢度试验;a02部分

颜色变化的灰度等级评定

din en 60068--2--70 environmentaltesting; part 2: tests;test xb:

abrasion of markings and letteringscaused by rubbing of fingers and hands

环境试验2部分:手和手指磨擦引起的标志及文字磨损

din en iso 105--e04textiles; testsfor colour fastness; part e04: colour fastness to perspiration

纺织品;染色色牢度试验;e04部分耐汗渍色牢度

3、testprocedure测试程序

procedures based on din en60068--2--70.

程序基于din en 60068--2--70

device according to din en60068--2--70.

设备依照din en 60068--2—70

3.1 fundamental information基本信息

a) mechanical loading机械负荷

the series of movements of a fingeror hand operation issimulated.

对手指或手动操作的动作进行系列模拟。

b) chemical influence化学物质影响

the influence of sweat, handlotions or other media can be taken into account by using test media (seesubsection 5.1).

汗水护手乳液或其他介质的影响可以考虑使用测试介质见第5.1。

c) endurance loading

due to variable clamping and testtravel paths, the procedure is suitable for components with curved structuredsurface and flat test samples.

基于可变夹持和测试行程路径测试程序适用于结构曲线表面与平坦表面的试验样品。

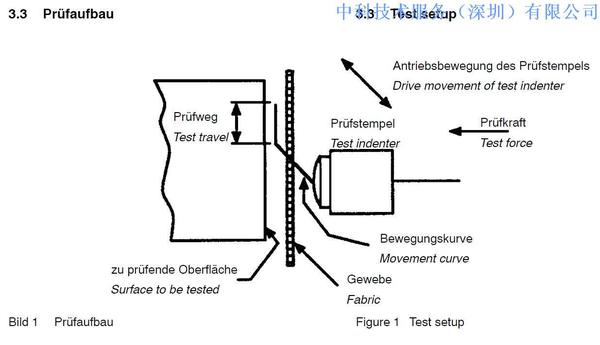

3.2 principle原理

a test indenter with a definedtesting force performs up to 10 million actuations. the geometry, material andhardness of the test indenter are designed such that a walking movement iscreated on the specimen surface.

硬度计压头以试验所定义的力执行10万次动作。硬度计压头的几何形状材料及硬度是确定的移动范围建立在工件表面。

by means of a test fabric that isloosely suspended between the test indenter and the specimen and that isprovided with a automatic fabric feed, a defined abrasion load is applied tothe surface. in addition, a test fluid can be applied in order to also simulatechemical loading.

测试纺织物松散的悬挂在硬度计压头与工件之间定义的摩擦负荷施加在表面上另外可以应用测试液体模拟化学药品加载。

3.4 device parameters设备参数

the specimens are tested understandard climate din 50014 (23 °c and 50 % relative humidity). prior to testingthe specimens must be cleaned with a fuzz-free cloth.

样件测试基于din50014标准温度23 °c相对湿度50 %测试前必须用绒毛布清洁。

the specimens are tested at ambienttemperature in accordance with their original structure.

when testing flat materials, thespecimens are supported as designed for their original structure.

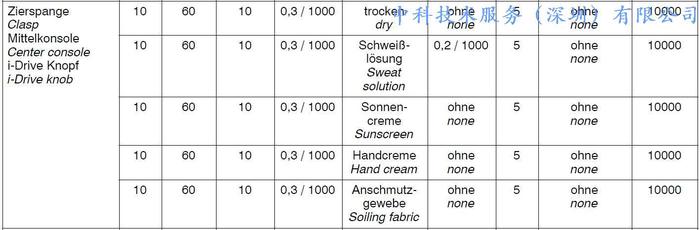

the testing parameters are definedin the technical delivery specification or group standards that applies to thecomponent or the material refer to annex a for conventional standard components

工件测试在室温下进行保持与原始结构一致测试平面材料时工件保持其结构设计。测试参数定义于交货技术规格或集团标准适用于零组件或材料。传统的标准组件请参阅附件a

4、evaluation评估

in order to remove the traces ofabrasion, the test specimens are cleaned after the abrasion test with theplastic maintenance emulsion (contains silicone) without applying pressure andwith a fuzz-free cloth. if necessary, additional cleaning with a micro-fibrecloth may be agreed upon.

为了消除悬浮磨损痕迹磨损试验后的的工件可以用塑料保养乳液包含硅绒毛布不施加压力擦拭。如有必要也可以考虑用微纤维布进行附加清洁。

in order to take recoverycharacteristics into account, evaluation of the cleaned specimens is carriedout 24 h after the test.

考虑恢复其特性样件经清理后需静置24小时再进行评估。

4.1 visual assessment视觉评定

evaluation is carried out understandard light d65. starting with a frontal view, the viewing angle is varieduntil maximum contrast is achieved.

评价需在标准光源d65下进行。起初用正视变换视角直到达到Zui大对比度。

the contrast of the traces ofabrasion to the untreated surface is evaluated by means of the gray scale asper din en 20105--a02 (grades 1 to 5). the evaluation shall be performed by atleast two persons with experience in assessing change of contrast with thisprocedure

磨损痕迹与的对比度判定依据din en20105 - a02等级1至5。评价其在测试中对比度的变化应当由至少两名有经验的人担任。

for materials that can not beade evaluated by means of the gray scale the evaluation is performedaccording to the subsequent scheme:

table 1 evaluation scheme forvisual evaluation of the abrasion behavior

如果不能充分由灰度进行评估则按照随后的图表评估

表格 1对磨损特性的可视化评价图表

|

index 索引 |

condition 条件 |

examples 示例 |

|

9-10 |

o. k. condition 合适条件 |

no change 无变化 |

|

8 |

o. k. condition 合适条件 |

--minimum surface luster / matting --minimum abrasion of the grain knolls or of the paint coat -Zui低表面光泽降低 -Zui低纹理磨损或油漆涂层磨损 |

|

7 |

the perception by the customer is notinfluenced noticeably. a deviation fromthe target value is perceived only by specialists.indication to improve the process / trendindicator. 对客户的品质影响不明显与目标值的偏差仅由专业人员察觉。注意过程改进/趋势检测。 |

--slight surface luster / matting --slight abrasion of grain knolls or of paoint coat --structure still unchanged --slight reversible deformation of surface. -轻微的表面光泽降低 -轻微擦伤颗粒或涂层 -结构仍然无变化 -轻微表面可逆的变形。 |

|

6 |

visual or haptic appearance of a feature that isperceptible by the customer. sensitization towards defects. 视觉或触觉的特征表现由客户感知。 对缺陷敏感。 |

-- clear surface luster / matting --clear abrasion of grain knolls or of paintcoat --structure slightly changed --slightly visible traces of abrasion fabric --slight permanent deformation. -清晰表面光泽消失 -清晰的颗粒或涂层磨损 -结构略有改变 -轻微的磨损痕迹可见面料 -轻微的变形。 |

|

5 |

unacceptable visual or haptic appearance of a feature that is clearly perceptible by the customer and that causes dissatisfaction. defect is usually complained about during nextvisit to the repair shop. 出现不可接受的视觉或触觉的特征可被明显察觉引起客户不满缺陷通常是抱怨 出现在下道工序装配车间 |

--significant surface luster / matting --structure barely perceptible anymore --traces of abrasion fabric are clearly perceptible --significant permanent deformation --permanent staining by soiling fabric -显著的表面光泽消失 -结构不再难以察觉 -织物的磨损痕迹很明显觉察 -重要的变形 -织物的着色污渍 |

|

4 |

visual defect with functional relevance and substantial impairment of the long -term (e.g. corrosion risk) or having potential to cause injury. defect can lead to unscheduled repair work in the shop. 视觉缺损与功能性相关的长期质量如腐蚀风险或潜在造成损害。 缺陷可能导致计划外维修。 |

--significant surface luster / matting --complete abrasion of the grain knolls and of the paintcoat --structure not perceptible anymore --destruction of material / surface. -显着的表面光泽消失 -彻底的涂层颗粒磨损 -结构不再明显 -材料/表面损毁 |

the permitted change is defined inthe technical delivery specification or group standard that is authoritativefor the component

note in case of plastic surfacesadditional light microscopical evaluation of the abrasion surface is possible.

允许的变化是定义于技术交付规格或集团标准授权的组件。

注对于塑料表面额外的光显微镜磨损表面的评价是合理的。

4.2 metrological appraisal计量评估

for a further examination withregard to the damage mechanism a metrological appraisal may be performed.

为了对损伤进一步探究可以应用计量评价。

by means of non-contact typescanning of the same surface before and after abrasion, the change in roughnesscaused by abrasion or the change of the maximum grain peak can be measured via thesurface analysis of the roughness using suitable test e (preferablylengthwise and transverse to the abrasion direction).

通过非接触的方式扫描同样的表面磨损前与磨损后的粗糙度改变或Zui大颗粒的变化可以用表面粗糙度测试设备量测纵向和横向磨损方向适用。

in addition, an image of the changed grain structure may beportrayed in 3-d by means of topographical representation.

此外晶粒结构改变的图像可以用地形学的方式描绘。

5、test agents

deviating test media and testfabrics are subject to prior agreement with the specialist departments.

测试介质和测试织物偏离均需获得专业部门的认可。

5.1 test media测试介质

-- plastic maintenanceemulsion(bmw-no.: 83 12 0 413 488)

--塑料保养乳液(bmw-no.: 83 120 413 488)

-- artificial sweat according todin en iso 105--e04 section 4.3 (alkaline)

--人造汗水按照din en iso105--e04 4.3部分碱性

-- skin care products (water-oildispersions) (e.g. oil of olaz, company p+g)

--护肤品(油水分散)

-- sunsreen (nivea sunspray waterresistant, spf 30,company beiersdorf

--防晒霜妮维雅防水防晒霜防晒指数30 妮维雅公司

-- hand cream (stokolan, companystockhausen)

--护手霜

-- distilled water with 0.5 % pril

--含0.5%洗洁精的蒸馏水

5.2 test fabric测试纺织物

-- standard fabric according to dinen 60068--2—70

-- soiling fabric company innowepfine abr--2056—02

未经允许,请勿擅自转载

联络人:mr vincent

检测电话:

电邮:cst_vincent@163.com

- 新解读GB 4806.6-2016食品接触用塑料树脂-国家 2017-04-07

- 新解读GB 4806.2-2015 食品安全国家标准 奶嘴 2017-04-07

- GB 4806.10-2016食品接触用涂料及涂层 2017-04-07

- 新解读GB 4806.10-2016食品接触用涂料及涂层 2017-04-07

- 新解读GB 4806.11-2016食品接触用橡胶材料及制 2017-03-31

- 新解读GB 4806.9-2016食品接触用金属材料及制品 2017-03-29

- 新解读GB 4806.9-2016 食品安全国家标准 食 2017-03-29

- 新解读GB 4806.7-2016食品接触用塑料材料及制品 2017-03-27

- 新解读GB 4806.7-2016 食品安全国家标准 食品 2017-03-27

- (RASFF)通报(2017年第8周) 2017-03-24